HEXON ENGINEERING CO., LTD.

Call us

02-1598318

sales@hexonengineering.com

HEXON AGITATOR

INTRODUCTION

AGITATORS MODEL

AGITATORS MODEL(2)

AGITATORS MODEL(3)

AGITATOR BLADE TYPE

AGITATOR BLADE TYPE(2)

SERVICES AND SUPPORT

INTRODUCTION

Hexon Engineering, a well-established engineering company, a provider of high quality & high performance of products, and including to engineering work consultancy. Our products are most reliable and acceptable on various industries for long-range period, ensuring state-of-the-art technologies and reliabilities.

Hexon’s products are being used in various processes, and our service including to:

- Agitators

- Storage Tanks, and Mixing Tanks.

- Gear Motor, Motor, and Spare Parts.

- Vacuum Pan Agitator for Sugar processes.

- Sugar Processing Equipment.

- Machinery Equipment.

- Engineering Consultancy.

HEXON provide standardize fabrication and installation conform to customer need, i.e. DIN, ANSI, BS, JIS standard or etc.

The fabrication is done under Hexon’ manufacturing planned and controlled. The inspection, test running is performed to ensure good quality of product is

delivering to client before commissioning.

HEXON AGITATORs are used in many validated process where the highest requirements are set for reliable design and satisfied performance.

- Chemical processing

- Food and Beverage processing

- Painting processing

- Pharmaceutical processing

- Pulp and Paper processing

- Petro Chemical processing

- Modified Starch processing

- Water Treatment processing

- Sugar Industries

AGITATORS MODEL

At Hexon, the obvious advantage of our agitator is that the various models suitable for process

technology. This is beneficial to flexible design to conform to process function, use minimize power

consumption, efficient use material, and suitable impeller blade type to process and mixing class.

Type MP and BP

(Motor Drive Agitator with Pulley Transmission)

Agitator type MP and BP is designed for using with driving unit

transmission speed, sample is motor with high speed and need to reduce, can be done by pulley transmission. This type is design for this application. The MP model have bearing box , inside have ball bearing unit on lower and top of bearing, inside housing is hollow shaft insert thru shaft sleeve, and fix locked to bearing for rotation, the BP type is same as Gb type but have spherical bearing with sleeve in middle and top for lock shaft. Above shaft is locking with pulley and transmission speed by belt, belt is calculated to conform with power used with more safety factor.

The normal use for this type if for medium to high speed agitation, benefit on non-expensive type agitator, and more convenience for maintenance, mixing volume is range from medium to large volume. This type is more benefit for lower cost to agitator and more convenience for using and maintenance, motor can change easily, and pulley belt can be replaced if damaged, pulley belt and find in local market with worldwide standard. The agitation task is suitable for blending, mixing, dispersion.

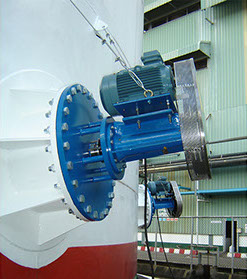

Type GB (Gear Drive Agitator with Additional Bearing)

Agitator type GB is designed for high torque transmission, driving unit is placed on bearing box, which

have additional bearing. The bearing box was designed to be rigid body, in middle of bearing box is seat

for bearing set, which consist of spherical bearing, sleeve, locking nut, and locking ring. Upper and lower

have bearing cover with oil seal to prevent grease leakage. This bearing type is more convenience for

remove and re-installation.

Above bearing box is driving unit that will be type of gear with hollow shaft, gear with solid shaft, or

motor direct drive.

Type MD (Motor Direct Drive Agitator)

This type of agitator is suitable for agitator that need speed

drive directly from motor, it normal use for high speed rotation,

the product need high pumping and circulation flow rate.

It is flexible to apply with various mixing processes. The shaft

of agitator is connected directly to shaft of motor. The speed

of agitator is high according to motor speed, e.g. 1450 rpm,

1000 rpm, 3000 rpm, in some curious design, shaft speed

pass thru critical speed. The absorbed vibration rubber is

required for this mixing to prevent shaft vibration and deflection.

Benefit to this type is consuming low power with high pumping

flow, convenience installation, easier using, and maintenance.

With non-expensive type for this, it was famous use

for small to medium volume mixing and non-high viscous

product. The agitation task can use with many processes e.g.

mixing, blending, keep storage.

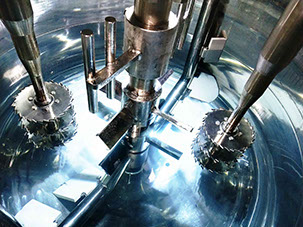

Type Homo and Premix

This type is design mostly use for pharmaceutical process, use

with high viscous product, need to make product to be homogeneously

material. Agitator need high speed of rotation and consume

high power, it can install on top of tank or bottom of tank.

The homo blade need to be precision with small clearance between

blade and stationary, that can make high shear to material

substance and this we need to put more energy in to system and

caused high power consumption.

Installation on bottom of tank must have mechanical seal to

prevent leakage of product. Premix blade also need to consider

to conform to process to be most efficient use of power and

mixing performance, blade type is unique designed especially for

specific process.

Mechanical seal will be designed conform to speed and product

type, it should be single acting mechanical seal or double acting

mechanical seal depended on function, the cooling system will be

consider for double acting mechanical seal. Homo mixer and

premix need to have more concern on installation operate and

maintenance, due to mechanical seal is critical point for this type

and make costly.

Type GS and GC (Gear Drive Agitator with Shaft, Coupling)

This type is flexible design for agitator that shaft can mounting

with gear unit directly. Normal design is agitator use shaft

insert to gear hollow, and locking on top of gear by screw, or

use disc locking type, it benefit for small volume mixing and

low cost design, the function of agitation is various from

blending, mixing, keep storage. This type also flexible for

moving and design with clamp lock. That benefit to user can

adjust batch mixing, process, and change mixing tank.

Vacuum Pan Agitator

Pans with mechanical circulation give a marked improvement in the boiling, and improve the quality

of product. They permit a valuable gain in purity of molasses and render possible work with tighter

massecuites. The correctly hydro dynamically designed propeller ensure the best fit calculation at

lowest power consumption, test and practical experienced prove the efficient of the massecuite

system:

- Compensates for the different in temperature of the vacuum pan. The transferred heat will be

increasing from the bottom towards the top of the pan, improving simultaneously the evaporation

speed.

- Homogenizing of the massecuite in the whole pan which can avoiding “ dead corner”, with out

exchanging in the massecuite process

- Boiling time can be reduced at unchanged steam pressure, and maintaining at lower boiling

temperature, which reduced fuel consumption will be obtained.

- Due to the reduction amount of conglomerates, this conveys to a corresponding reduction in the

centrifuging time, and a reduction in the consumption of usage water for washing the sugar.

- Leading to Improvement centrifuging processes due to the small variation in crystal sizes.

- Differences in the super saturation throughout the pan can be avoided.

AGITATOR BLADE TYPE

Mixing task is vary conform to product property such as viscosity, density, and flow rate. Also other

property such as shear rate is consider whether is Newtonian fluid or non-Newtonian fluid, mixing

torque of system needed are an importance impact to impeller design. From the basic requirements and

mixing task function, possible of impeller shape, the best suitable is chosen to suit with agitation duty.

The power consumption, Pv is proportion to, product density(ñ), speed(n), and blade diameter(d2), as

formulas.

Pv ~ ñ X n^3 x d2^5

The calculation can specify power consumption for each blade type, and most efficient use of driving

unit selection.

AG102-4

Blade type: AG102-4

Low to medium viscosity, High pumping capacity application AG102: Blade characteristic is propeller 3 blade with continuous pitch. This type is normal design for flow control, which can produce pumping circulation overall to tank. This propeller type is construct of 3 blades with pitch incline continuous degree,

with much more blade area on the edge can help for increase pumping capacity. Rotation with clock, liquid will be pumped into lower of tank and turn on to top of tank. Normally use for mixing low to medium viscous product, blending, heat transfer, and keep suspension function. In some high viscous mixing process, also use this type e.g. Lime mixing Process use is various e.g. chemical mixing, pulp paper, waste water, milk storage, crude oil blending, sugar re-melt, sugar

vacuum pan.

AG104

Blade is large propeller for vacuum pan.

This type is large size of propeller blade, use for vacuum pan in sugar industries, use with high viscous product , the blade is design with high strength absorption and can be split type for easier on installation and maintenance.

AG302-8

Blade type: AG302, AG304, AG306, AG308

Low to medium viscosity, mixing, high pumping flow application

AG302 : Impeller is beam with 2 blade, pitch angle 45 degree.

AG304 : Impeller is beam with 4 blade, pitch angle 45 degree.

AG306 : Impeller is beam with 6 blade, pitch angle 45 degree.

AG308 : Impeller is trapezoidal beam with 2 blade pitch angle

45 degree.

This type blade is design for medium to high pumping, it can use

many application, the blade beam with pitch 45 degree, can

pumping to axial flow and radial flow. Liquid can circulated

overall direction. This blade can perform many function e.g.

mixing, blending, or suspension. The vicious of product is

various from low to high viscosity, but famous use for low to

medium viscosity, and high viscous for some application. The

blade type 4 blade or 6 blade is use for high pumping and high

mixing performance needs, e.g. re-melting solid particle, dissolve

high viscous oil, lime mixing, this type need medium to high shear

force, and consuming more power.

Process use is various e.g. chemical mixing, beverage mixing, waste water, reactor process, vegetable oil mixing, mining agitation process, and ethanol process.

For trapezoidal beam is normal use for save energy and can make high pumping flow same as blade beam. The process type is various from low to high viscosity product.

Blade type : AG502-4

Medium to high viscosity, high shear application.

AG502 : Blade characteristic is 6 disc turbine, straight blade 90 degree. This type is use with medium to high viscous product, the main duty is for high shear function, and dispersion, liquid flow will pumping to radial direction much more than axial direction, It can make shear force to product directly, that can

break powder, solid particle or emulsion to small size, this is benefit for this type.

This type is normal use in mixing process, dissolve solid to

liquid, high viscose emulsion, painting powder dissolve, gas

mixing. This blade can produce high shear and consuming

high power, the structure of agitator should rigid to prevent

vibration. It also normal use in bio-process, pharmaceutical,

fermentation tank, ethanol process.

HEXON Facilities

Hexon have own facilities work shop that can support work design, fabrication, testing. Quality control in process is need for us intervene the production is carrying. Also technical team for analyst data and determine solution. The continuous improvement from experience, mistake, and real performance in process is adapted to each design new similar process.

Quality

With working closely to customer engineer, we realize that our customer demand high quality product manufactured, service, timely, and efficient manner. Working and service for long

time in this filed we are fully aware of specific demand and high standard that customer need to achieve, this normal need quality such as food, pharmaceutical process standard is applied to our work environment.

Guarantee

All of agitator is design based on process data from customer, we can warrantee mixing result, and performance use as well. The mechanical warrantee is included by our scope to ensure to

customer satisfaction. The equipment that use in produce agitator is based on recognize standard and guaranteed brand name, such as driving unit, motor, bearing unit, this is to ensure final product can perform in good condition.

After Sales and Service

We have our own service team to support customer, such as installation team, with many of year experience, our technician team understand and known problem on using and installation. We can prevent and suggest potential mistake to customer, and guideline for correct operating method. Even after test run if problem occurred, we also help to

monitor and solve the issue with in the warrantee period.

Copyright © 2020 by Hexon Engineering Co., Ltd.

ABOUT US

We are an engineering company. Manufacturers of machinery for various industries. Have experience and gained more than 20 years

WORK TIME

We work 6 days a week, every day excluding major holidays. Contact us if you have an emergency, with our Hotline and Contact form.

Monday - Friday: 8.00AM - 5.00 PM

CONTACT US

Office : 52/1 Moo8, Sainoi-ladbualuang Rd.,

Sainoi District, Nonthaburi 11150

TELL: 02-1598318 (Fax.): 02-1598319

EMAIL: sales@hexonengineering.com